Prodotti

- Parti di attrezzature da taglio

- Parti elettriche per la lavorazione del legno in generale

- Parti della macchina bordatrice

- Parti della serie CNC

- Componenti per la lavorazione del legno in generale

- Altre parti per la lavorazione del legno

- Viti e bulloni per lavorazione del legno

- Dadi e rondelle per lavorazione del legno

- Rivetti per lavorazione del legno

- Ancoraggi per lavorazione del legno

- Lubrificanti per la lavorazione del legno

- Pistole per grasso per lavorazione del legno

- Distributori di olio per lavorazione del legno

- Calibri per lavorazione del legno

- Strumenti di allineamento laser per la lavorazione del legno

- Nastri di misurazione per la lavorazione del legno

- Livelli di lavorazione del legno

- Attrezzatura protettiva per la lavorazione del legno

- Prodotti per la pulizia della lavorazione del legno

- Saldatura trave per lavorazione del legno

- Altri pezzi Homag

- Ricambi BIESSE/SCM

- Parti di Nanxing

- Parti KMS

- Parti SCM

- Parti KIMS

- Parti della macchina per avvolgimento

- Parti del trasportatore a rulli

- Piccola attrezzatura per la lavorazione del legno

- Ricambi per Macchine Biesse

- Ricambi per macchine Homag

- Ricambi per macchine SCM

- Testa laser

Prodotti in evidenza

Contattaci

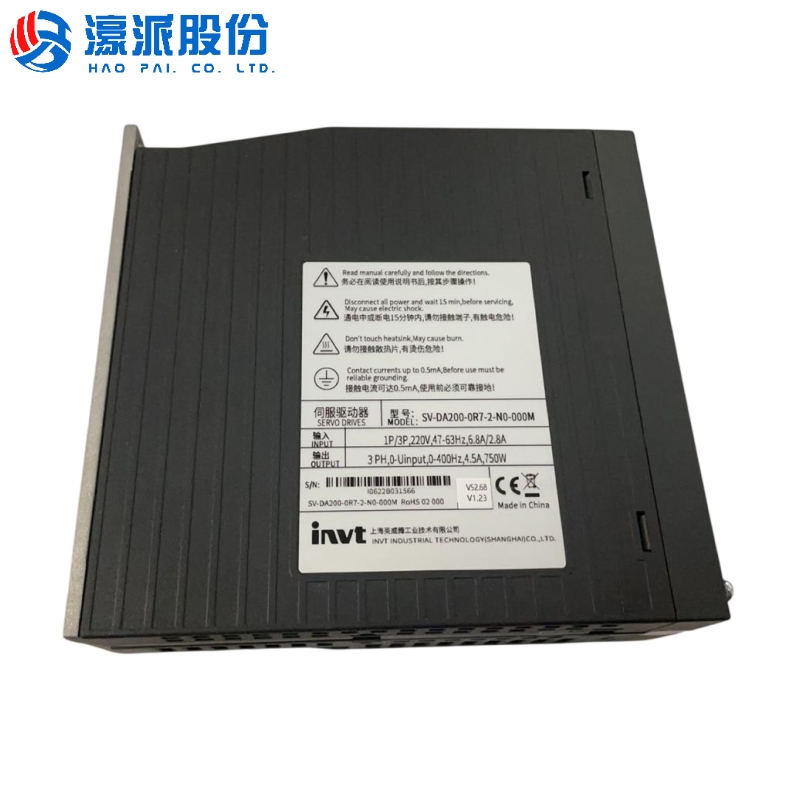

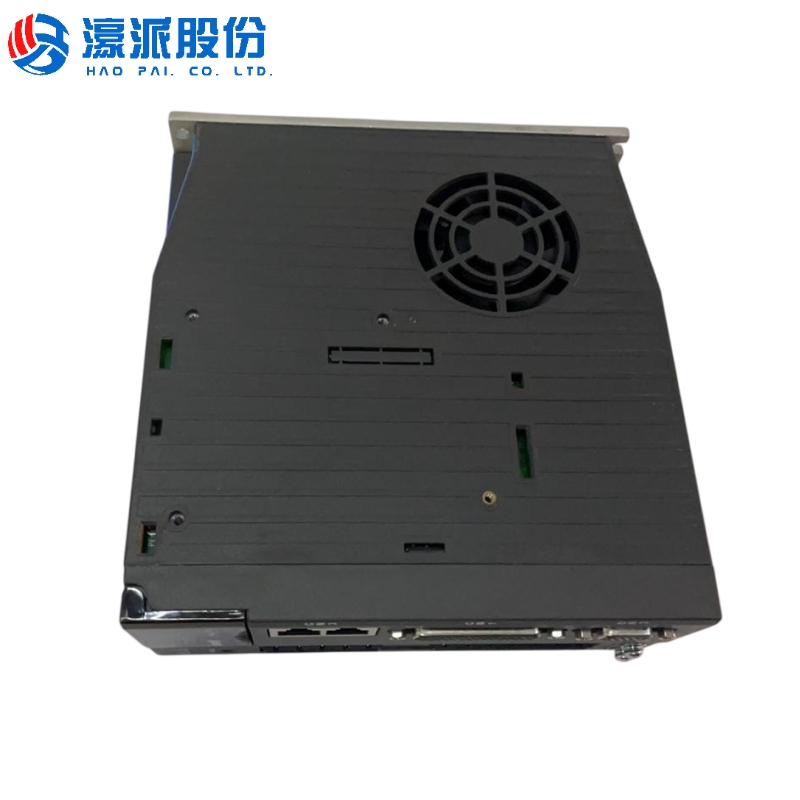

Driver CNC

- INVT

- Cina

- 2-3 giorni

- 10 pezzi al mese

- SV-DA200-0R7-2-N0-000M

- 4,5 A 750 W

Product Advantages and Features

1.Ultimate Servo Performance

-Velocity-response bandwidth: 2 kHz; extremely short settling time; positioning repeatability down to ±0.01 mm.

-23-bit single-turn absolute encoder with 0.15 arc-sec resolution; zero position is retained even after power loss

2.Full Closed-Loop & Linear-Motor Support

-Optional second encoder or glass-scale for true full closed-loop control, completely eliminating mechanical backlash.

-Direct-drive, sensorless linear-motor operation: velocity-loop bandwidth ssshhh1 kHz, position settling <5 ms, travel distance for detection <2 mm; includes runaway protection

3.Rich Motion-Control Functions

-On-board 128-segment internal position table—multi-point positioning without external PLC.

-3,600-point electronic cam curve with automatic smooth interpolation between every two points; one-click product changeover

4.Intelligent Vibration Suppression & Compensation Algorithms

-4 auto/manual notch filters (50–5,000 Hz) + low-frequency damping + disturbance observer, drastically reducing noise and end-point vibration.

-Online/offline load-inertia identification + friction-torque compensation, cutting commissioning time significantly

5.High-Speed Industrial Fieldbus & User-Friendly Software

-EtherCAT standard, synchronizing up to 64 axes with 125 µs cycle time.

-PC-based ServoPlorer V4.0: real-time scope, frequency-response test, batch parameter copy, plus complete built-in manual

6. Proven in Key Industries

-Already in volume use in robotics, LED die bonders, Li-ion battery winders, glass CNC engravers and other high-end equipment, delivering ssshhh80 % throughput increase

Product Technical Parameters

| Power Rating | 750 W |

| Main Circuit Supply | Single-phase / three-phase 220 VAC 50/60 Hz (±10 % permissible fluctuation) |

| Continuous Output Current | 5.0 A rms |

| Peak Current | (3 s) 15 A rms |

| Encoder Feedback | 23-bit multi-turn absolute encoder (0.15 arc-sec resolution) |

| Velocity Response Bandwidth | 2 kHz |

| Pulse Command Input | Differential: 4 Mpps Open-collector: 200 kpps |

| Electronic Gear Ratio | 1 / 10 000 – 1 000 ×Internal |

| Position Table | 128 points, positioning via communication |

| Built-in Functions | Full closed-loop, electronic cam (3 600 points), linear-motor drive, auto gain tuning, vibration filters |

| Communication Interface | EtherCAT (CoE protocol, DC synchronization, cycle 125 µs – 4 ms) |

| Analog Inputs | Speed command: DC ±10 V, drift suppression 0.3 mV |

| Torque command: DC ±10 V, drift suppression 4.88 mV | |

| Control Modes | Position / Speed / Torque / Full closed-loop / EtherCAT distributed-clock synchronization |

| Digital I/O | Inputs: 8 programmable (pulse, direction, home, probe, mode switch, etc.) |

| Outputs: 6 programmable (positioning complete, speed reached, alarm, brake, etc.) | |

| Protection Functions | Hardware: Over-voltage, under-voltage, over-current, over-speed, overload, over-temperature, brake-resistor overload, encoder fault Software: Parameter error, position deviation, EEPROM fault |

| Environmental Conditions | Operating: 0 – 45 °C / 90 % RH non-condensing Storage: –20 – 80 °C |

| Protection Class | IP20 (cabinet installation) |

| Dimensions (W × H × D) | Approx. 55 mm × 170 mm × 160 mm (subject to actual product) |

| Certifications | CE / UL / cUL / RoHS |

Product Application Scope

Electronics Manufacturing.

High-speed die bonders, SMT pick-and-place machines, semiconductor sorting / test equipment.

Li-battery & PV.

Electrode winding machines, stacking machines, laser welders, tab welding machines.

Robotics & Manipulators.

SCARA, Delta, six-axis articulated robots and gantry-type manipulators.

Precision Machining.

Glass / sapphire engraving & milling machines, high-gloss finishing machines, CNC tool magazines, turret controls.

Packaging & Printing.

Multi-axis color-register printing presses, vertical / pillow packaging machines, gantry synchronous cutting lines.

Textile & Special.

purpose Equipment – Warp knitting machines, embroidery machines, high-speed coil winders, new-energy energy-storage assembly lines.

Product Description

Ideal for electronics, lithium-battery, photovoltaic, packaging and precision-machining industries that demand nanometer-level repeatability and micro-second multi-axis synchronization.

Company Introduction

Haopai Co., Ltd. was established in 2008 and is a comprehensive service enterprise specializing in machinery and accessories for the home industry. We have a specialized and innovative customer center, component assembly workshop, equipment debugging workshop, processing workshop, and warehousing. Our main business includes sales of mechanical parts, equipment upgrades and renovations, equipment maintenance and relocation, customized non-standard equipment, intelligent production line planning, automation support, machine vision, shared cloud warehouses, etc. We provide customers with professional personalized services. After more than ten years of accumulation and development, our elite service team of nearly 200 people has served over 10000 enterprises nationwide. Over the years, we have accumulated more than 200000 non-standard accessory categories, making us the most comprehensive one-stop procurement platform in the industry. We have the most competitive technical renovation team in China, with a total of over 100000 equipment upgrade and renovation projects. Haopai Co., Ltd. has been committed to the great cause of making global machinery and preferred Chinese parts for many years, and is determined to become the preferred brand for comprehensive services of global machinery and parts.

Deeply Cultivating the Industry for More Than Ten Years, Creating an Intelligent Manufacturing Full Chain System for Woodworking Machinery.

After 16 years of industry accumulation, we have always focused on the research and manufacturing of CNC woodworking machinery. We have established a leading full chain production system and specialized team structure, providing one-stop services from research and development to delivery for global customers. It is currently a one-stop procurement platform with a complete range of categories in the industry.

Specialized and Innovative Customer Center

Haopai has been committed to the business philosophy of quality first, integrity-based, and win-win cooperation. We adhere to the business philosophy of ultimate customer experience and efficient operation, and uphold the service spirit of taking non-standard customization, drilling difficulties, and solving difficulties as our own responsibility. We constantly innovate and aspire to become the preferred brand for comprehensive services of global machinery and accessories. We are committed to making the great cause of global machinery and preferred Chinese accessories contribute to the development of national brands and the strength of Haopai people.

Team Style

Professional team, always on standby

The service team is distributed in pre-sales consulting, order management, technical support, and after-sales service positions, with 7 × 12 hours of online response to ensure that your needs are processed in the first time.

Haopai Intelligent Cloud Warehouse, Escorting You

In Order to Solve the Problems of High Procurement Costs, Low Efficiency, Difficult Management, Slow Logistics, And High Stagnant Inventory of Industrial Materials in Factories, Haopai Shared Cloud Warehouse Emerged in 2020. Greater Efforts Will Be Made to Assist Customers in Achieving Zero Capital Occupation, Spare Parts Inventory, And Improving Their Digital Level.

Machining Workshop

Component Assembly Workshop

New Media Center

The Intelligent Dispatching System Established in 2021 Has Achieved Intelligent Personnel Allocation, Real-Time Control of Technical Personnel's Work Status, Mobile Dispatching, Accurate and Effective Arrangement of Various Tasks, Precise Control of Project Costs, Thus Creating a Fast Response, Efficient, And Professional After-Sales Service Team.

Patent Certificates

Cooperative Partner

We Have Served over 10000 Enterprises Nationwide and Have Accumulated over 200000 Non-standard Accessory Categories over the Years, Covering Major Home Furnishing Brands Across the Country.